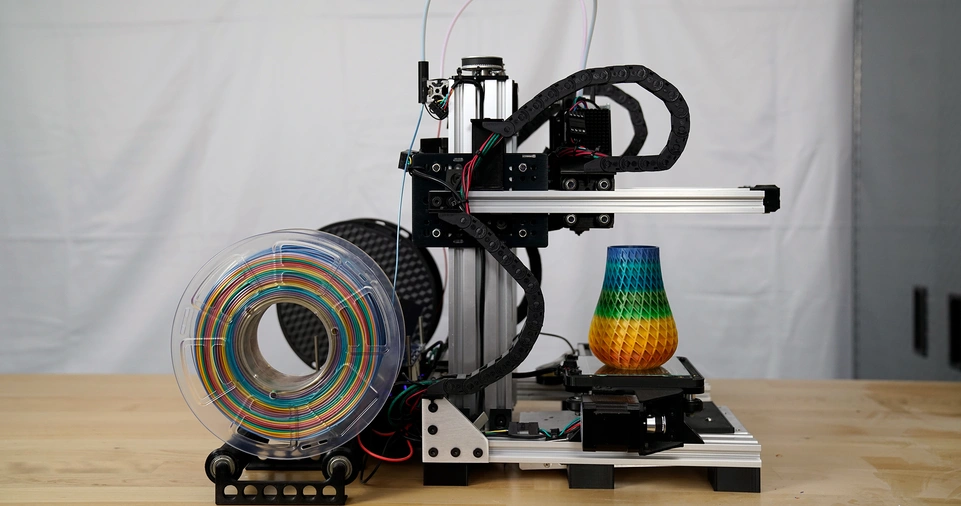

3D printing has revolutionized DIY projects, allowing makers to create custom objects, replacement parts, and artistic designs with ease.

Whether you’re a hobbyist, entrepreneur, or educator, understanding how to use a 3D printer can open up endless possibilities.

This guide will cover everything from selecting the right printer to mastering design software, optimizing printing settings, troubleshooting common issues, and applying advanced post-processing techniques.

Understanding 3D Printing Technology

Before diving into DIY projects, it’s essential to understand how 3D printing technology works.

The process involves converting a digital 3D model into a physical object by adding material layer by layer. The main types of 3D printing technologies include:

- Fused Deposition Modeling (FDM): The most common method that uses thermoplastic filament.

- Stereolithography (SLA): Uses liquid resin cured by a laser for high precision.

- Selective Laser Sintering (SLS): Uses powdered materials fused with a laser for industrial-grade parts.

Choosing the Right 3D Printer

Selecting the right printer is crucial for achieving high-quality prints. Here are the primary types of 3D printers:

| Type of Printer | Features | Best For |

|---|---|---|

| FDM | Uses filament, affordable, widely available | Beginners, prototyping, functional parts |

| SLA | High precision, uses liquid resin | Jewelry, miniatures, dental applications |

| SLS | Uses powdered material, industrial-grade | Advanced prototyping, functional end-use parts |

Essential Materials for 3D Printing

Choosing the right material impacts durability, flexibility, and usability. Below are common materials used in 3D printing:

| Material | Properties | Common Uses |

|---|---|---|

| PLA | Biodegradable, easy to print | Toys, prototypes, household items |

| ABS | Strong, heat-resistant | Mechanical parts, enclosures |

| PETG | Tough, water-resistant | Food containers, medical devices |

| TPU | Flexible, durable | Wearable items, shock absorbers |

| Resin | High detail, brittle | Miniatures, jewelry |

Setting Up Your 3D Printer

- Unboxing and Assembly – Some printers come pre-assembled, while others require manual setup.

- Leveling the Print Bed – Ensures even adhesion and prevents print failures.

- Loading Filament – Insert and heat the filament according to the printer’s specifications.

- Calibrating the Printer – Run test prints to fine-tune settings.

- Updating Firmware – Keep software up-to-date for optimal performance.

Designing 3D Models for Printing

To create custom objects, you need 3D modeling software. Popular options include:

| Software | Difficulty Level | Features |

|---|---|---|

| Tinkercad | Beginner | Easy to use, browser-based |

| Fusion 360 | Intermediate | Advanced modeling, parametric design |

| Blender | Advanced | Sculpting, animation, rendering |

You can also download pre-made models from repositories like Thingiverse, MyMiniFactory, and Cults3D.

Slicing and Preparing for Printing

Before printing, a 3D model must be converted into a series of layers using slicing software. Popular slicing tools include:

- Cura (Free, beginner-friendly)

- PrusaSlicer (Optimized for Prusa printers)

- Simplify3D (Paid, advanced features)

Key settings to adjust in slicing software:

- Layer Height – Affects print resolution.

- Infill Percentage – Determines internal strength.

- Print Speed – Balances speed and quality.

- Supports – Needed for overhanging parts.

ALSO READ: How to Grow a Lush Lawn Without Chemicals?

Printing and Troubleshooting

Once the model is sliced, transfer the file to the printer via USB, SD card, or Wi-Fi. Common printing issues and solutions include:

| Problem | Cause | Solution |

|---|---|---|

| Warping | Uneven cooling, unlevel bed | Use a heated bed, apply glue stick |

| Stringing | Excessive filament oozing | Reduce temperature, enable retraction |

| Layer Shifting | Loose belts, unstable printer | Tighten belts, place printer on stable surface |

| Under-Extrusion | Clogged nozzle, incorrect settings | Clean nozzle, check extrusion rate |

Advanced Printing Techniques

To improve quality and efficiency, consider these techniques:

- Dual Extrusion Printing – Print in multiple colors or materials.

- Vase Mode – Prints seamless objects with a single outer wall.

- Adaptive Layer Heights – Improves print details where needed.

- Support-Free Printing – Optimize model orientation to minimize supports.

Post-Processing Techniques

Post-processing improves aesthetics and durability. Techniques include:

- Sanding – Smooths rough surfaces.

- Painting – Adds aesthetic appeal.

- Acetone Vapor Smoothing – Works with ABS prints to create a glossy finish.

- Resin Curing – Essential for SLA prints to harden fully.

- Heat Treatment – Improves mechanical properties of prints.

DIY Project Ideas Using 3D Printing

Here are some exciting DIY projects you can create with a 3D printer:

| Project | Description |

|---|---|

| Custom Phone Stand | A personalized stand for your device |

| Wall Hooks | Durable and stylish hooks for organization |

| Prosthetic Hand | 3D printed prosthetics for a good cause |

| RC Car Parts | Customize or repair remote-controlled cars |

| Personalized Keychains | Unique designs with initials or logos |

| Drone Accessories | Print custom parts for drones |

| Kitchen Gadgets | Measuring spoons, bottle openers, organizers |

| Gardening Tools | Planters, hose connectors, plant markers |

| Educational Models | Print anatomy models, math aids, and more |

Safety Considerations

While 3D printing is fun and creative, safety precautions should be followed:

- Ventilation – Resin and certain filaments emit fumes; use in a well-ventilated area.

- Fire Safety – Never leave a running printer unattended.

- Protective Gear – Use gloves and masks when handling resins or sanding prints.

- Electrical Safety – Use surge protectors and avoid overloading circuits.

Future of 3D Printing in DIY

The future of 3D printing is promising, with advancements in:

- Bioprinting – Printing human tissues for medical applications.

- Recycled Filaments – Using waste materials for sustainable printing.

- AI-Enhanced Slicing – Automating and optimizing print settings.

- Multi-Material Printing – Printing objects with varied textures and properties.

ALSO READ: How to Make a Small Room Look Bigger and Brighter?

Conclusion

Mastering 3D printing for DIY projects takes time, but with the right tools and knowledge, you can create custom, functional, and artistic objects.

Whether you’re printing household items, functional parts, or creative designs, a 3D printer is an invaluable tool for makers. Start experimenting today and bring your ideas to life!

By following this guide, you can enhance your skills and turn your creative visions into tangible objects using 3D printing.